Milk Cooling Tank With Copeland Refrigeration Unit

Milk cooling tank can be devided into vertical milk cooling tank and horizontal milk cooling tank according to the tank capacity. For small capacity, such as 500L, 800L and 1000Liter capacity milk cooling tanks, we usually make it into vertical milk cooling tanks. For the cooling capacity more than 1500L, we usually make it into horizontal milk cooling tanks.

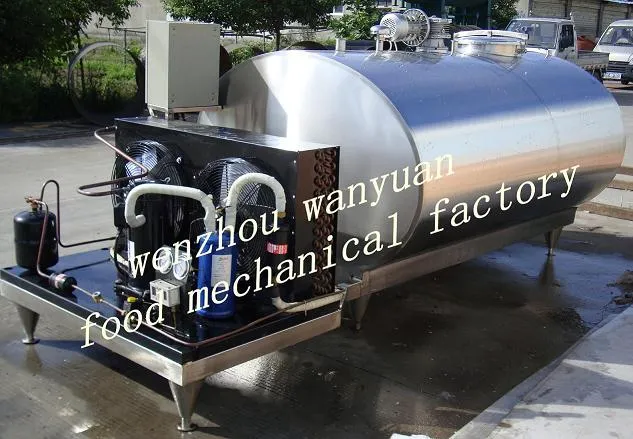

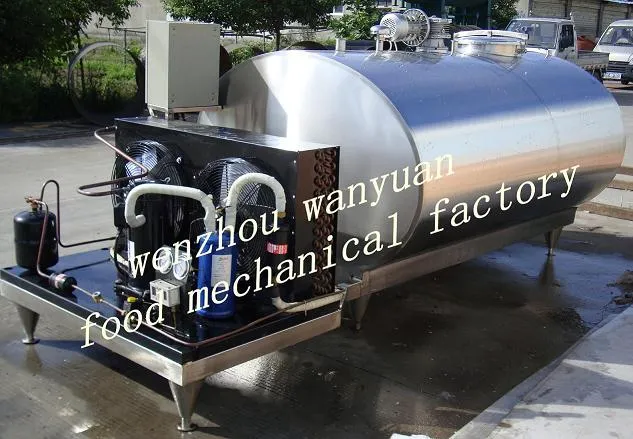

Horizonal milk cooling tank is mainly used in cooling to storage sweat milk or other liquid. It is designed based on international advanced technology and is equipped with imported compressor and safety protection system, micro computer monitor, as polyurethane foaming, honeycomb board evaporator. So the milk cooling tank is the most ideal cooling and storage equipment for farm, milk factory, food factory, beverage factory and pharmacy industry.

Vertical milk cooling tank is an insulating layer wrapping the jacketed layer, which keeps it in constant temperature and prevents the milk from producing bacterium. The timed agitator makes the fresh milk keep in A grade.

The milk cooling tank body is made of 304 Stainless Steel with good appearance and polished of welding line. With agitator at stirring speed- 36rpm. With insulating material to keep the temperature in cold storage.

Wenzhou Wanyuan Food Mechanical Factory---3000 Liter Milk Cooling Tank Insulated Milk Cooler

Wenzhou Wanyuan Food Mechanical Factory---3000 Liter Milk Cooling Tank Insulated Milk Cooler

Here below the milk cooling tank specification

Milk cooling tank can be devided into vertical milk cooling tank and horizontal milk cooling tank according to the tank capacity. For small capacity, such as 500L, 800L and 1000Liter capacity milk cooling tanks, we usually make it into vertical milk cooling tanks. For the cooling capacity more than 1500L, we usually make it into horizontal milk cooling tanks.

Horizonal milk cooling tank is mainly used in cooling to storage sweat milk or other liquid. It is designed based on international advanced technology and is equipped with imported compressor and safety protection system, micro computer monitor, as polyurethane foaming, honeycomb board evaporator. So the milk cooling tank is the most ideal cooling and storage equipment for farm, milk factory, food factory, beverage factory and pharmacy industry.

Vertical milk cooling tank is an insulating layer wrapping the jacketed layer, which keeps it in constant temperature and prevents the milk from producing bacterium. The timed agitator makes the fresh milk keep in A grade.

The milk cooling tank body is made of 304 Stainless Steel with good appearance and polished of welding line. With agitator at stirring speed- 36rpm. With insulating material to keep the temperature in cold storage.

Wenzhou Wanyuan Food Mechanical Factory---3000 Liter Milk Cooling Tank Insulated Milk Cooler

Wenzhou Wanyuan Food Mechanical Factory---3000 Liter Milk Cooling Tank Insulated Milk CoolerHere below the milk cooling tank specification

| Milk cooling tanks specification | |||||

| Model | Capacity(L) | Cooling capacity(W) | Stirring speed ( R/MIN) | Match power(KW) | dimension(L*M*H) |

| MCT-0.5 | 500 | 3500 | 36(24)R/MIN | 1.5 | 2200*1350*1150 |

| MCT-1 | 1000 | 6900 | 36(24)R/MIN | 3 | 2750*1150*1500 |

| MCT-1.5 | 1500 | 10000 | 36(24) R/MIN | 4 | 3000*1350*1550 |

| MCT-2 | 2000 | 13000 | 36(24)R/MIN | 5 | 3200*1500*1600 |

| MCT-3 | 3000 | 17800 | 36(24)R/MIN | 6.5 | 3500*1650*1700 |

| MCT-5 | 5000 | 34000 | 36(24)R/MIN | 13 | 4000*1950*2000 |

| MCT-6 | 6000 | 34000 | 36(24)R/MIN | 13 | 4200*2200*2100 |

| MCT-8 | 8000 | 42000 | 36(24)R/MIN | 18 | 4800*2400*2400 |

| MCT-10 | 10000 | 65000 | 36(24)R/MIN | 24 | 5000*2600*2500 |